It's really simple. See that little bolt with two nuts on it in the picture below? That is inserted into the actuator plunger hole, and it keeps the fork engaged at all times. Basically it acts like the AWD sleeve does, but crappier. The only down side is that it does throw a service 4WD light every time you put it into 4WD, because the plunger is not allowed to actuate all the way.

One way around that last issue is to fabricate a plate to go over the actuator opening, and just using a longer bolt to perform the same function. As a result though, the actuator must be mounted/hung elsewhere in the chassis.

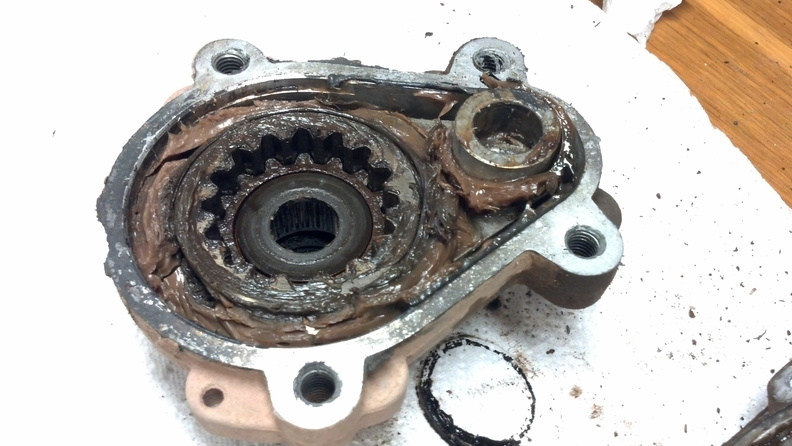

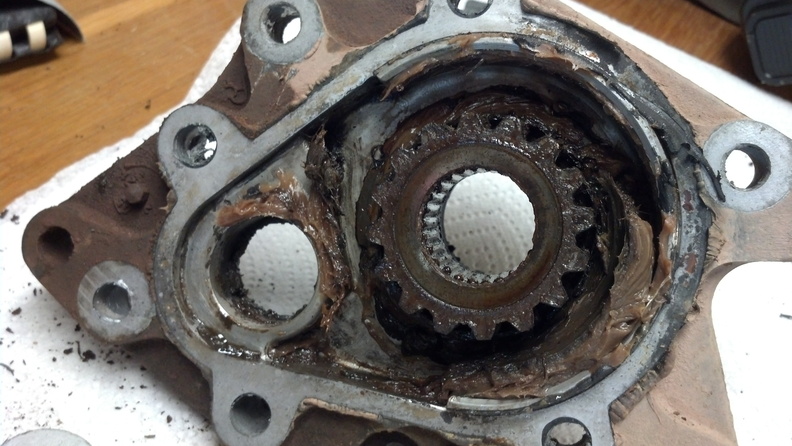

After a teardown of using this method for a year and a half, the parts seem to be wearing normally, and the needle bearings seem to be in good shape. After the prior year and a half of equivalent use, but without this "poor man" mod, my bearings had died - for a second time. Anyways, here are the pictures from the poor man mod teardown. Pretty good overall.

This time, rebuilding for the disconnect for the 4th time, it was fixed the right way:

This is the AWD sleeve from the Bravada. GM part number 12471636. Really just putting that there for people to find in the future. Cheapest I could find it was about $70.

The last item I wanted to play with was adding a grease zerk, to allow greasing of the two outer bearings without taking the CV out, or taking the disconnect apart. There's a perfect spot on the outer collar.

Drilled a 7/32" hole. The zerks seem to be 1/4-24 thread.

I didn't have a tap for fine thread, so I only tapped one thread worth (to get a bite), and then had to force the zerk in to place.

This is where the fitting drops the grease:

Mounted, the zerk is accessible without removing anything: