Your observations about the tie rod pivot point are fascinating, but I don't see them as tied to the UCA flip. Have to investigate for sure. Thanks!

Lauron wrote:

So the problem is finding out the actual dimensions of a suitable short outer end. The Moog spec only gives you part info. Anybody else have a source for the tie rod end dimensions or has some one identified a short 16 mm outer that matches our spindle with or without the need to reamer the spindle?

Thanks,

Ron

Lauron wrote:To strengthen the tie rod, I would bump the rod size to 16 mm expecting to match up a male heim with a male outer tie rod end through an adjustable straight tube with weld in left and right hand thread tube adapters.

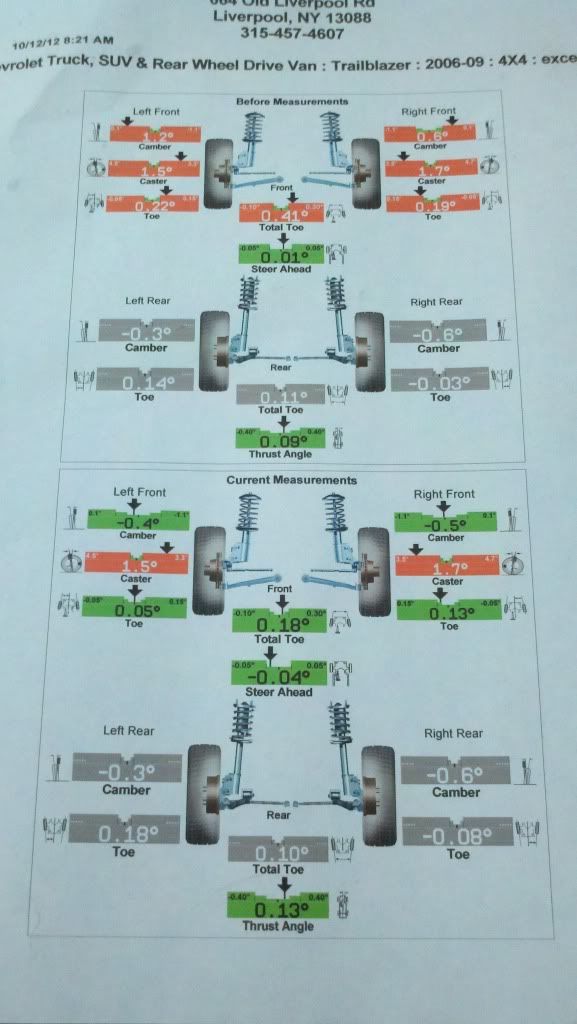

Lauron wrote:What was really revealing to me was the change in toe in when I flexed the suspension.

The bds drawing and discussion may help. The principle is the UCA, LCA and Tierod must line up at the instant center with the outer and inner pivot points also lined up to avoid bump steer. With unequal length arms, I believe zero bump steer only happens at one position over some range of travel, not full suspension travel.

So, if the LCA is moved out, the inner tie rod end needs to move out as well. Of course the outers are not moved from their alignment.

JamesDowning wrote:Your proposed test could definitely test your theory. It would be interesting to compare the results, but I would suggest that you also retake your 'as is' measurements again before you put the spacer in.

Bigger than toe issues, I'm curious where your caster is. Caster plays a rather big role in highway stability.

navigator wrote:JD, I would call caster front/back lean and camber in/out lean.

I'll admit I don't understand all the dynamics of it but I wouldn't think caster to be too big of a deal compared to camber.

It would seem camber would affect how much tire touches the ground.

After flipping my UCA everything came back in spec for me except caster as well.

HARDTRAILZ wrote:I think of caster as rake on a motorcycle.

Most vehicles are not sensitive to caster changes but too much on a big lifted truck will make it harder to steer.

navigator wrote:JD, I would call caster front/back lean and camber in/out lean.

I'll admit I don't understand all the dynamics of it but I wouldn't think caster to be too big of a deal compared to camber.

It would seem camber would affect how much tire touches the ground.

After flipping my UCA everything came back in spec for me except caster as well.