It seems my front-end disconnect is acting up on me. I don't know how long it hasn't been working, but I assume it's fairly recently. I actually first noticed it when rotating my tires, as I normally throw it into 4WD to hold the front wheels still while I tighten the lugs.

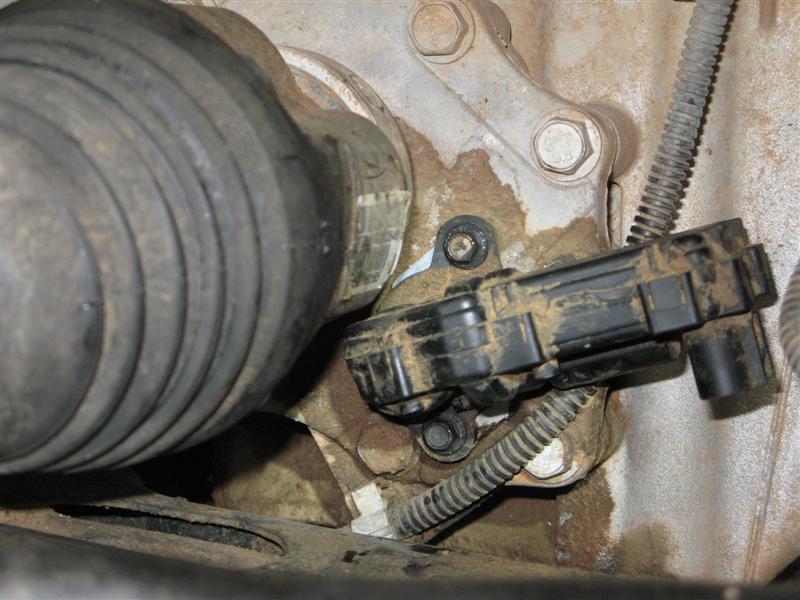

This is the splined disconnect housing. The actuator is the strange-shaped black plastic part.

So, my symptoms are as follows, no 4WD light, yet no front connection at the splined disconnect. So this leads me to beleive that the front actuator/plunger is working properly. From my searching, it seems that the actuator does not provide positive traction to the syncro-shift fork, but it provides a spring force. This is done because the syncro will not always align properly with the splines of the intermediate shaft. So the actuator can apply pressure so the syncro will snap into place as soon as the splines align.

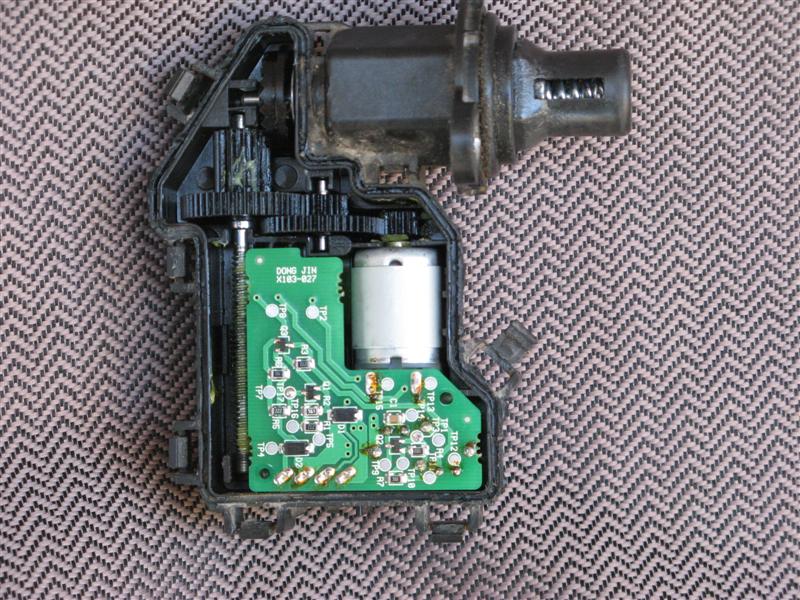

The internals of the actuator. Notice the spring in the plunger.

So because my actuator is operating properly, I have some sort of mechanical problem in my disconnect. I'm assuming I have one of these three issues... misalignment of the input and output splines, so that the syncro will not snap over the intermediate shaft splines... not enough grease, and the syncro has gotten stuck... or a broken shift fork.

Click the following picture for a detailed view:

I notice there are a A4WD and S4WD front axle actuator option. The A4WD option having no disconnect, and only a solid connector. I wonder if it would be possible to just replace the front spline and shift fork with a single solid connector. We can still stick the actuator in the housing so we don't receive and error codes at the computer.

Anyways... this is my start to looking into this issue... I haven't even had time to take a real good look at the actuator yet. Is there any insight from anyone? Anything to be careful of, or to take special note of?

Thanks guys!

Pine Barrens Wheelin!

Pine Barrens Wheelin!