Just to make sure I had a thread here so it would come up in a search.

Been posting on the OS for over four years that these goofballs are incompetent machinists and have lousy customer support, but not everybody gets the memo. Ezaccessory sells a lot of spacers, but I implore everybody to just say no to their low prices.

4x4forLIFE just had a stud spin in its seat on the spacer, trapping his wheel, and possibly damaging the spacer even if he gets the nut cut off.

Also points out another justification for anti-seize on lug nuts.

Never use Ezaccessory.com for spacers

18 posts

• Page 1 of 1

-

The Roadie - Founder

- Posts: 5013

- Joined: Mon Sep 07, 2009 11:29 pm

- Location: OR, Portland area

- Name: Bill Carton

- Vehicle Year: 2004

- Vehicle: GMC Envoy

- DriveTrain: 4WD w/ G80

- Rank: Expedition Guide

And where do you put the antiseize? I followed the advice on Fred's website and other sources and used blue threadlocker on the hub studs, but nothing on the spacer studs.

And if they really used grade 8 bolts like the guy said, I'm not entirely sure how good that is vs using real studs which were designed for that.

And if they really used grade 8 bolts like the guy said, I'm not entirely sure how good that is vs using real studs which were designed for that.

This is an aggressive post. You probably won’t like it. It is quite doubtful that you have the taste or sophistication to be able to appreciate a post of this quality and depth.

Build Thread

Build Thread

-

KE7WOX - Veteran

- Posts: 1226

- Joined: Tue Sep 29, 2009 2:10 pm

- Location: OH, Dublin (Columbus)

- Name: Felipe G

- Vehicle Year: 2004

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

The sad part is that most "newb" type people don't know to search first to see if there is a reason why a part is so cheap, they just buy it and find out the hard way. I've learned that in most cases you get what you pay for.

MarcMC - Bilstien - BDS - WheelAdapters - Treadwright - K&N - Gibson - Hayden - Zone

My Build Thread

My Build Thread

-

tbangert - Off-Roader

- Posts: 157

- Joined: Mon Jun 07, 2010 5:05 pm

- Location: ME, Berwick

- Name: Tyler

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

It is nice to have the perfection of Fred but the function and better cost on ebay still

they've always worked for me.

-

HARDTRAILZ - Moderator

- Posts: 6342

- Joined: Sat Sep 12, 2009 1:49 am

- Location: IN, Batesville

- Name: Kyle

- Vehicle Year: 2006

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Extreme Offroader

Hence why I used the other vendor, wheeladaptor or whatever his name is. Good service, great product, and 20k lifted miles later, no problems (blue loctite on ALL threads).

My Build Thread | 2006 Trailblazer LS Desert Camping Edition **SOLD**

2013 Nissan Xterra S "ReXterra"

2013 Audi S4 6MT Prestige "Brunhilde"

2013 Nissan Xterra S "ReXterra"

2013 Audi S4 6MT Prestige "Brunhilde"

-

Philberto - Lifer

- Posts: 2049

- Joined: Fri Sep 11, 2009 5:30 pm

- Location: CA, Camarillo

- Name: Philip Cruz

- Vehicle Year: Other

- Vehicle: Other Vehicle

- DriveTrain: 4WD

- Rank: Offroad Rated

Yep, 27k on my 'wheeladapters' adapters. Not one problem at all.

Build Thread

Back to stock, had fun while it lasted...

Back to stock, had fun while it lasted...

- janesy86

- Veteran

- Posts: 1291

- Joined: Thu Sep 10, 2009 2:29 pm

- Location: MA, Salem

- Name: Nick Janes

- Vehicle Year: 2007

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ G80

- Rank: Offroad Rated

janesy86 wrote:Yep, 27k on my 'wheeladapters' adapters. Not one problem at all.

Going on 40k myself- so far, so good.

3...2...1....FIRE IN THE HOLE!!!

-

gotspeed1 - Trail-Blazer

- Posts: 294

- Joined: Tue Sep 22, 2009 9:02 pm

- Location: Woodland Park, CO

- Name: Joey

- Vehicle Year: 2002

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

- Rank: Offroad Rated

I just realized I now have over 100,000 KM with my adapters (6x5 -> 6x5.5) and half of the USA!

They have been absolutely great - Sam's Offroad.

AG

They have been absolutely great - Sam's Offroad.

AG

|| Documenting and sharing overland travels ||

|| adventures and expeditions ||

|| Trailblazer modifications ||

-

AlekG - Off-Roader

- Posts: 116

- Joined: Tue Sep 15, 2009 9:29 pm

- Location: Guelph, Ontario, CANADA

- Name: Alek

- Vehicle Year: 2006

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Expedition Rated

Just a little comparison by SpyderTrax

Domestic vs. Import Wheel Spacers: Mechanical & Material Analysis

September 2nd, 2010 T. Kingston No comments

1. Introduction

The seemingly unending debate of outsourcing & offshoring is back on top of America’s “What Matters Most†list. As the proud co-owner of Spidertrax Off-Road, an American company that designs & manufactures its products in-house, it should come of no surprise what side of this debate I sit. My interests however in publishing this article lie not in politics but in engineering ethics, focusing not on “you get what you pay for†but rather “you didn’t get what was advertisedâ€.

Below is a detailed mechanical & material analysis between a Spidertrax JK Wheel Spacer (Domestic) & an “Unnamed Brandâ€* JK Wheel Spacer (Import). The take away here is not so much one product being superior to another. The issue is with the import wheel spacer being advertised as using 6061-T6, the same high quality material used in our domestic wheel spacer. Although these claims leave the impression that both products are virtually identical, the analysis detailed below tells another story.

*Before moving onto the results, I wanted to clear up any confusion ahead of time regarding the use of “Unnamed Brandâ€. The conflict in sharing this identity comes from singling out just one manufacture as we have duplicated these same test results from other import wheel spacer manufacturers. So, in an effort in “taking the high road†the import manufacture in this test will remain nameless and be referred to only as “Unnamed Brandâ€.

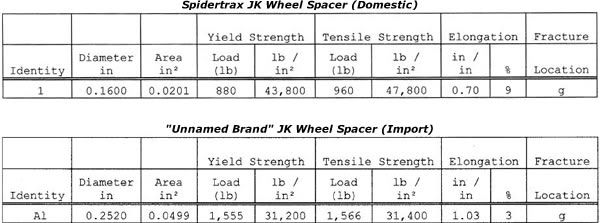

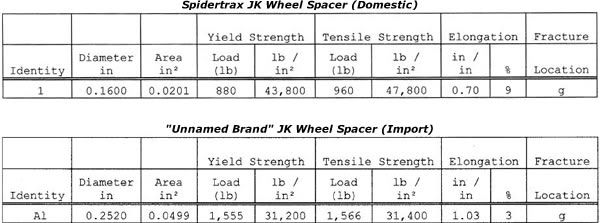

2a. Tensile Test (Aluminum Spacer)

Both domestic and import JK wheel spacers are advertised as using “6061-T6†aluminum. As referenced on MatWeb, Aluminum 6061-T6 should provide a minimum Tensile Strength (Yield) of 40,000 psi & a minimum Tensile Strength (Ultimate) of 45,000 psi.

As shown above, our domestic wheel spacer exceeds the minimum requirements for 6061-T6 (as advertised). The import wheel spacer, on the other hand, is off nearly 35% in terms of Tensile Strength for 6061-T6 (not as advertised). What is just as, if not more, concerning is the closeness in value between Yield Strength and Tensile Strength for the import spacer. This closeness in value suggests the material is cast and not billet (also not as advertised).

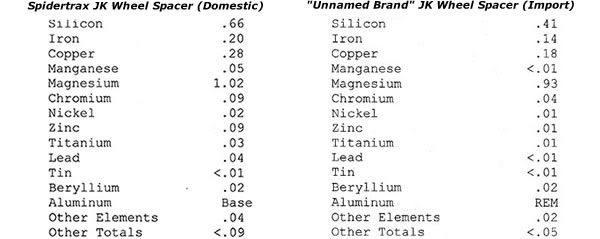

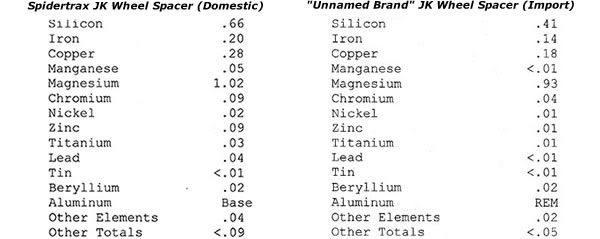

2b. Chemical Analysis (Aluminum Spacer)

This test confirms that, although there are differences in material composition as shown below, both our domestic wheel spacer & import wheel spacer conform to a 6061 series grade.

There is an important distinction made when combining the results of both the tensile test & chemical analysis though. When combined, the results clearly show our domestic wheel spacer is indeed billet 6061-T6 (as advertised) while the import wheel spacer is cast 6061 (not as advertised).

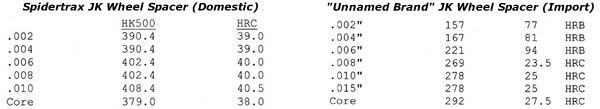

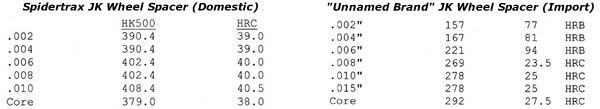

2c. Hardness (Wheel Stud)

The last test is a cross sectional hardness traverse on the wheel stud (a component which is pressed into the wheel spacer).

The results, as per SAE J429, indicate our domestic wheel stud exceeds Grade 8 specification (as advertised) while the import wheel stud meets Grade 5 specification (not as advertised).

3. Conclusion

As shown in the above analysis our domestic wheel spacers are manufactured from billet 6061-T6 aluminum and run Grade 8 wheel studs as advertised. Although the import wheel spacer is advertised using these same high quality materials, the above analysis proves it is manufactured out of nothing more then cast 6061 running Grade 5 wheel studs. “Buyer Beware†certainly doesn’t capture these outrageous findings.

For reference, you can also download a copy of the complete Domestic & Import metallurgical reports. All testing as detailed in this article was performed by Colorado Metallurgical Services (CMS). Spidertrax Inc. (Spidertrax Off-Road) is not affiliated with or a subsidiary of CMS.

Found Here-- http://blog.spidertrax.com/

Domestic vs. Import Wheel Spacers: Mechanical & Material Analysis

September 2nd, 2010 T. Kingston No comments

1. Introduction

The seemingly unending debate of outsourcing & offshoring is back on top of America’s “What Matters Most†list. As the proud co-owner of Spidertrax Off-Road, an American company that designs & manufactures its products in-house, it should come of no surprise what side of this debate I sit. My interests however in publishing this article lie not in politics but in engineering ethics, focusing not on “you get what you pay for†but rather “you didn’t get what was advertisedâ€.

Below is a detailed mechanical & material analysis between a Spidertrax JK Wheel Spacer (Domestic) & an “Unnamed Brandâ€* JK Wheel Spacer (Import). The take away here is not so much one product being superior to another. The issue is with the import wheel spacer being advertised as using 6061-T6, the same high quality material used in our domestic wheel spacer. Although these claims leave the impression that both products are virtually identical, the analysis detailed below tells another story.

*Before moving onto the results, I wanted to clear up any confusion ahead of time regarding the use of “Unnamed Brandâ€. The conflict in sharing this identity comes from singling out just one manufacture as we have duplicated these same test results from other import wheel spacer manufacturers. So, in an effort in “taking the high road†the import manufacture in this test will remain nameless and be referred to only as “Unnamed Brandâ€.

2a. Tensile Test (Aluminum Spacer)

Both domestic and import JK wheel spacers are advertised as using “6061-T6†aluminum. As referenced on MatWeb, Aluminum 6061-T6 should provide a minimum Tensile Strength (Yield) of 40,000 psi & a minimum Tensile Strength (Ultimate) of 45,000 psi.

As shown above, our domestic wheel spacer exceeds the minimum requirements for 6061-T6 (as advertised). The import wheel spacer, on the other hand, is off nearly 35% in terms of Tensile Strength for 6061-T6 (not as advertised). What is just as, if not more, concerning is the closeness in value between Yield Strength and Tensile Strength for the import spacer. This closeness in value suggests the material is cast and not billet (also not as advertised).

2b. Chemical Analysis (Aluminum Spacer)

This test confirms that, although there are differences in material composition as shown below, both our domestic wheel spacer & import wheel spacer conform to a 6061 series grade.

There is an important distinction made when combining the results of both the tensile test & chemical analysis though. When combined, the results clearly show our domestic wheel spacer is indeed billet 6061-T6 (as advertised) while the import wheel spacer is cast 6061 (not as advertised).

2c. Hardness (Wheel Stud)

The last test is a cross sectional hardness traverse on the wheel stud (a component which is pressed into the wheel spacer).

The results, as per SAE J429, indicate our domestic wheel stud exceeds Grade 8 specification (as advertised) while the import wheel stud meets Grade 5 specification (not as advertised).

3. Conclusion

As shown in the above analysis our domestic wheel spacers are manufactured from billet 6061-T6 aluminum and run Grade 8 wheel studs as advertised. Although the import wheel spacer is advertised using these same high quality materials, the above analysis proves it is manufactured out of nothing more then cast 6061 running Grade 5 wheel studs. “Buyer Beware†certainly doesn’t capture these outrageous findings.

For reference, you can also download a copy of the complete Domestic & Import metallurgical reports. All testing as detailed in this article was performed by Colorado Metallurgical Services (CMS). Spidertrax Inc. (Spidertrax Off-Road) is not affiliated with or a subsidiary of CMS.

Found Here-- http://blog.spidertrax.com/

-

OregTrailBlazin - Off-Road Vendor

- Posts: 610

- Joined: Wed Sep 09, 2009 2:34 pm

- Location: OR, Grants Pass

- Name: Johnathan Kurz

- Vehicle Year: 2004

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

-

Opeth - Addict

- Posts: 846

- Joined: Tue Oct 05, 2010 4:46 pm

- Location: NY, Solvay

- Name: Cody

- Vehicle Year: 2006

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

- Rank: Trail Ready

Sounds like the import parts just don't have the correct heat treatment. Instead of being T6, they're closer to a T4 or T3. The importers may have started with 6061-T6 billet, but once they cast the material, the heat treatment properties change.

That's the nice thing about billet/stock material, the quality is much more controlled - and you know what you're getting in the end. The issue, however, is that there is much more machining - and thus more cost in a true billet part.

That's the nice thing about billet/stock material, the quality is much more controlled - and you know what you're getting in the end. The issue, however, is that there is much more machining - and thus more cost in a true billet part.

-

Trail X - Founder

- Posts: 9925

- Joined: Mon Sep 07, 2009 10:22 pm

- Location: VA, Roanoke

- Name: James Downing

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Expedition Guide

My wheel spacers are from here  . I recently saw this post on active topics and saw "ezaccessory", I thought it looked familiar. I went to ebay to look at the vendor of my spacers, saw the same name, got that bad feeling in the pit of my stomach

. I recently saw this post on active topics and saw "ezaccessory", I thought it looked familiar. I went to ebay to look at the vendor of my spacers, saw the same name, got that bad feeling in the pit of my stomach  . I used loctite on all threads and haven't had a problem. I gotta change them right? im paranoid about the stud spinning in place in an emergency.

. I used loctite on all threads and haven't had a problem. I gotta change them right? im paranoid about the stud spinning in place in an emergency.

-

Stoked - Off-Roader

- Posts: 130

- Joined: Mon Oct 18, 2010 10:19 am

- Location: Miami, FL

- Name: Juan

- Vehicle Year: 2006

- Vehicle: Other GMT360/370

- DriveTrain: AWD

- Rank: Offroad Rated

I wouldn't change them. The stud won't spin after it's tightened down - that's only an issue on initial installation. And if you regularly check the torque when you rotate tires every 5000 miles, they'll be safe. I wouldn't have known their customer support skills were non-existent if I hadn't been a customer at first, and another member now has those spacers and we both beat on them.

-

The Roadie - Founder

- Posts: 5013

- Joined: Mon Sep 07, 2009 11:29 pm

- Location: OR, Portland area

- Name: Bill Carton

- Vehicle Year: 2004

- Vehicle: GMC Envoy

- DriveTrain: 4WD w/ G80

- Rank: Expedition Guide

That makes me feel a little better since this is the family car. I followed some tips Philberto posted in http://forums.offroadtb.com/viewtopic.php?f=14&t=26&p=23565#p23565 about retightening, torque specs, etc. However I will keep a close eye on the spacers, thanks Roadie.

-

Stoked - Off-Roader

- Posts: 130

- Joined: Mon Oct 18, 2010 10:19 am

- Location: Miami, FL

- Name: Juan

- Vehicle Year: 2006

- Vehicle: Other GMT360/370

- DriveTrain: AWD

- Rank: Offroad Rated

That other member is me... I've had them on, will be 2 years in April. I check them each time a tire comes off. I've had to remove them once to do brakes. They have held up. If I had to get another set, I would go with a different supplier, though.

Mario - Build Thread

-

Gordinho80 - Lifer

- Posts: 2787

- Joined: Tue Sep 08, 2009 9:27 am

- Location: NJ, Jackson

- Name: Mario Almeida

- Vehicle Year: Other

- Vehicle: Other Vehicle

- DriveTrain: 4WD

Glad I could help out. I'm still sitting pretty on mine, and I feel that after the initial settling-in of both spacer material and studs, you should be able to torque with loctite and just check the torque every oil change or so... and since you should be rotating tires every oil change, no extra work is involved.

My Build Thread | 2006 Trailblazer LS Desert Camping Edition **SOLD**

2013 Nissan Xterra S "ReXterra"

2013 Audi S4 6MT Prestige "Brunhilde"

2013 Nissan Xterra S "ReXterra"

2013 Audi S4 6MT Prestige "Brunhilde"

-

Philberto - Lifer

- Posts: 2049

- Joined: Fri Sep 11, 2009 5:30 pm

- Location: CA, Camarillo

- Name: Philip Cruz

- Vehicle Year: Other

- Vehicle: Other Vehicle

- DriveTrain: 4WD

- Rank: Offroad Rated

I can't remember who it was.but that I just read.about it a week ago or so. And he got the ez spacers and like on two of the spacers 4 bolts on each spacer "popped" out essentially making everythin just spin.

I've had my spacers on since last year or something and mine are fine as the day I bought them. I got wheel adapters.

I've had my spacers on since last year or something and mine are fine as the day I bought them. I got wheel adapters.

Go Big & Go Broke

-

SteveTB03 - Addict

- Posts: 600

- Joined: Fri Sep 11, 2009 6:11 pm

- Location: Las Vegas, NV

- Name: Steve Darras

- Vehicle Year: Other

- Vehicle: Other Vehicle

- DriveTrain: 4WD

- Rank: Trail Ready

Yeaaa never buy these spacers. Absolutely garbage. I did do a search but not untill AFTER i placed my order.  BUT on a happier side i have custom wheel spacers for sale. 6X5 TO 4xsomething

BUT on a happier side i have custom wheel spacers for sale. 6X5 TO 4xsomething  LOL heres a pic of the POS... i took a look at one of the lugs that literally fell out and the grooves where its supposed to be "seated" into the spacer were eithe so worn down or just.. non exsistant. VERY VERY POOR QUALITY. Took a hammer to the rest ofthe studs and with basically a 3 year olds strength knocked out the other studs

LOL heres a pic of the POS... i took a look at one of the lugs that literally fell out and the grooves where its supposed to be "seated" into the spacer were eithe so worn down or just.. non exsistant. VERY VERY POOR QUALITY. Took a hammer to the rest ofthe studs and with basically a 3 year olds strength knocked out the other studs

BUT on a happier side i have custom wheel spacers for sale. 6X5 TO 4xsomething

BUT on a happier side i have custom wheel spacers for sale. 6X5 TO 4xsomething  LOL heres a pic of the POS... i took a look at one of the lugs that literally fell out and the grooves where its supposed to be "seated" into the spacer were eithe so worn down or just.. non exsistant. VERY VERY POOR QUALITY. Took a hammer to the rest ofthe studs and with basically a 3 year olds strength knocked out the other studs

LOL heres a pic of the POS... i took a look at one of the lugs that literally fell out and the grooves where its supposed to be "seated" into the spacer were eithe so worn down or just.. non exsistant. VERY VERY POOR QUALITY. Took a hammer to the rest ofthe studs and with basically a 3 year olds strength knocked out the other studs

-

4x4forLIFE - Cruiser

- Posts: 27

- Joined: Mon Dec 14, 2009 6:35 pm

- Location: Hamilton, NJ

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

18 posts

• Page 1 of 1