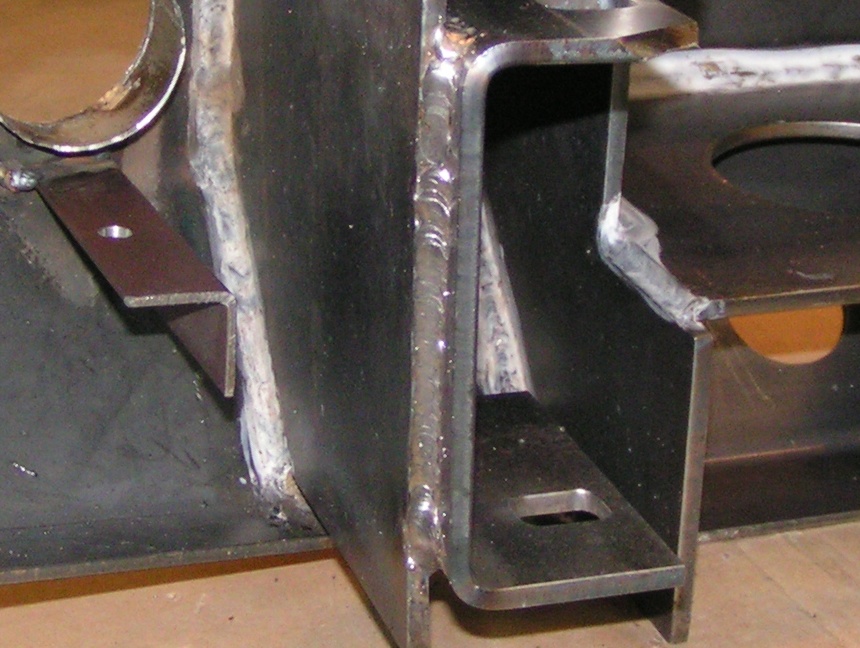

Backing up the rear compression tubes is another chunk of tube inside the bumper, basically acting as a compression block to feed the load directly into the frame instead of bending the top plate of the bumper. It also ties the frame bracket to the side plate of the center box.

I also added a chunk on the outboard uprights:

That one doesn't accomplish much, basically it just keeps the tube from locally distorting the top plate with a moment, spreading the load into the corner of the bumper.

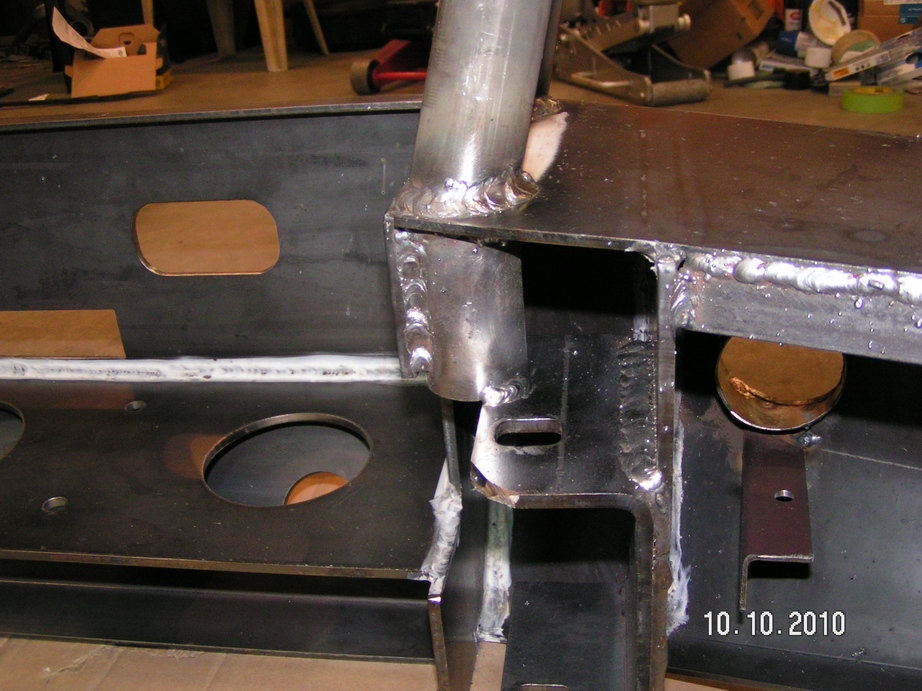

You can see I also added a hefty angle along the back edge of the top plate. This was done to stabilize the edge of the top plate. It's probably overkill, but if something hits the corner of the bumper hard enough to fold the wing, the point of failure will be the compression crippling of the edge of that top plate allowing the plate to buckle, taking the rest of the bumper with it. By simply stabilizing that edge and keeping it straight, much strength is added to the whole wing of the bumper.

I know the weld looks especially crappy on that angle, but it's not critical so don't worry about it. I was just wasting wire at that point.

I didn't have KMA cut holes for the fog lights because I wasn't really sure if they'd fit, where I wanted them, how the bumper was constructed, etc. Knowing what I know now I'd have them do it to save me the effort. I'd have them move the 5" light hole outboard a couple inches or inboard about 6 inches and put the little hole outboard of it so they don't look so crowded.

It's a 2.5" hole for Hella Micro DE fogs. I did put a chunk of tube behind it like KMA did with the big hole:

The big lights are 100 watt KC's, with the driving light beam pattern (supplied by KMA).