I couldn't see the point of doing anything serious without kicking the front axle center line forward. When you take into consideration that even 35s can hit the firewall it just makes sense. In addition you effectively move chassis weight rearward and make your approach angle drastically better.

By the time you realize this point you recognize you're starting from scratch. The stock pickup points don't really work anymore. The diff needs to move forward, the shock towers need to move to accommodate the change and the longer travel coil overs... basically everything just goes to hell as far as stock is concerned.

I can think of a few ways to do long travel IFS within the confines of the stock subframe with a rear sump pan. You could probably even just lengthen the stock a arms and CV shafts and get some really good travel out of 33s. Positioning the rack might be interesting, but maybe doable if sufficiently motivated. I've been thinking about it on the envoy as a stock based system.

But as you turn it over in your head more you realize that you kinda got to start from scratch. We got some decent bumpsteer lifted as is. When you're looking at making a new subframe, a arms, etc, bump steer is the least of your issues. It's some nice icing on the cake. But it's easily dealt with... and you're still gonna have some at the extremes.

Eventually you're going to crunch the numbers, agonize over everything and then you're going to build it and then the real world will creep in and everything will be off to some degree or another. I gave up and decided to build it all from scratch copying many guys before me. I got a little hung up initially trying to make the suspension deliver the best travel numbers and after some correction on various boards, I realized they weren't doing anything special and they were just treating it like the tried and true road race car suspensions I was already familiar with.

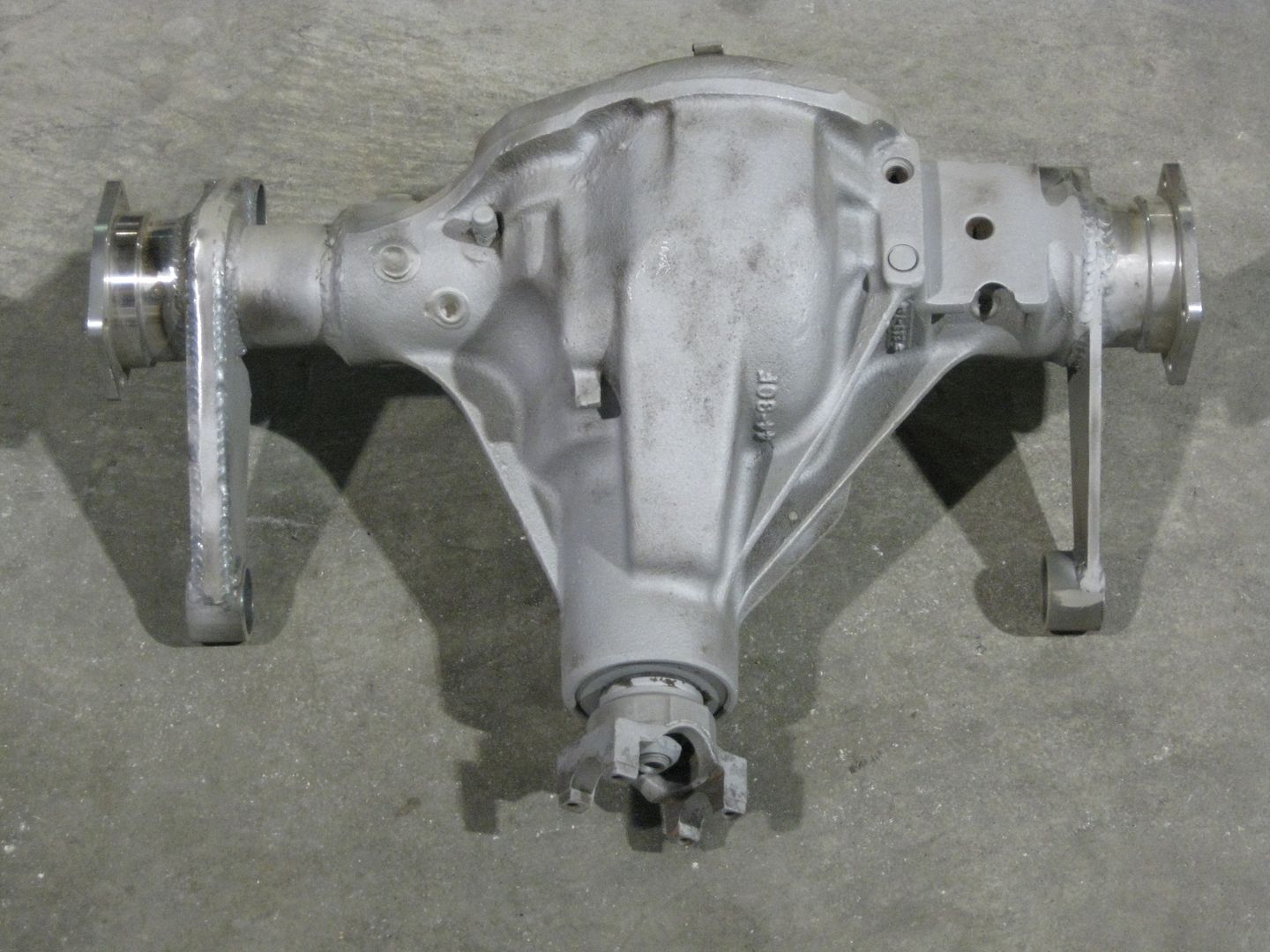

I completely gave up working on stock suspension and just decided to build it all. There's a lot of merit to using stock components. I chose to go with .25 and .50 steel for a new spindle. It's as heavy as your average walmart shopper using a motorized cart, and it's not optimum in any way, but I'm confident it'll hold up. The hub comes from a 3500 chevy with an ABS reluctor ring that is the same count as our lowly trailblazer. We'll see how that translates.

In the pic the steering mount will be added last.

Was just made aware the picture was clipped...

.

.