You figured me out.

Auto deflators are nice time savers, the PITA is adjusting them to your preferred pressure.

On Board Air

Forum rules

Threads must fully document the modification with pictures and verbiage in the first post.

Threads that do not meet this criteria may be moved or deleted.

Threads must fully document the modification with pictures and verbiage in the first post.

Threads that do not meet this criteria may be moved or deleted.

33 posts

• Page 2 of 2 • 1, 2

-

Trail X - Founder

- Posts: 9925

- Joined: Mon Sep 07, 2009 10:22 pm

- Location: VA, Roanoke

- Name: James Downing

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Expedition Guide

like it,also like the use of the copper tubing. seems it can conform well and stay tucked away easier, less zip ties.

-

dirty anton - Trail-Blazer

- Posts: 426

- Joined: Thu Aug 19, 2010 12:21 am

- Location: upper marlboro md

- Name: mike

- Vehicle Year: 2002

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Extreme Offroader

dirty anton wrote:like it,also like the use of the copper tubing. seems it can conform well and stay tucked away easier, less zip ties.

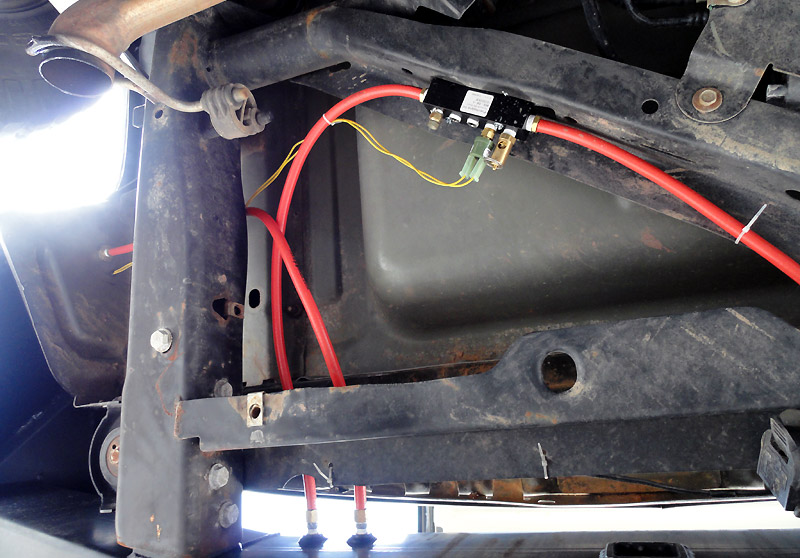

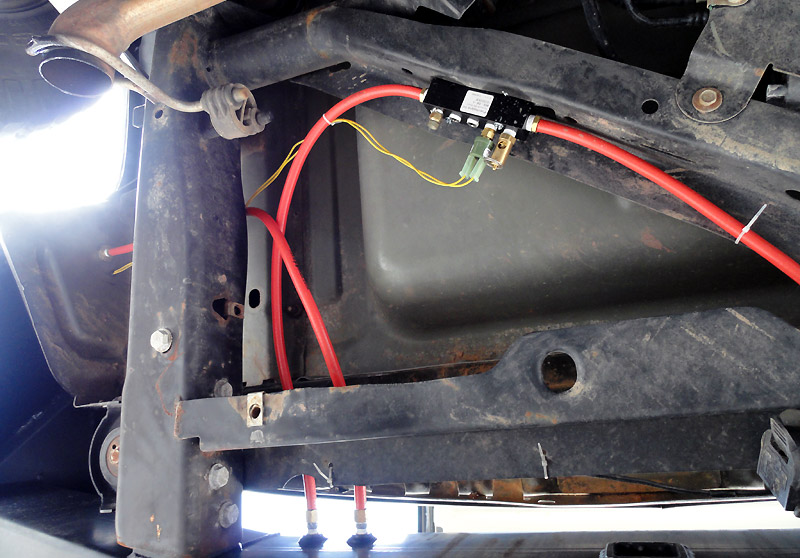

My big worry was getting rubber air lines too close to the exhaust manifold... but yeah, just a few zip ties to the body lift blocks and a couple other places.

I own too many vehicles now. Let's leave it at that.

The old Trailblazer - Build

The old Trailblazer - Build

-

fishsticks - Moderator

- Posts: 4358

- Joined: Thu Apr 01, 2010 11:30 pm

- Location: WA, Castle Rock

- Name: Donny

- Vehicle Year: Other

- Vehicle: Other Vehicle

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Extreme Offroader

If you went down the let side of the vehicle you could probably run it inside the frame and avoid the exhaust.

-

djthumper - Moderator

- Posts: 2702

- Joined: Wed Mar 24, 2010 6:04 pm

- Location: NV, Las Vegas

- Name: Larry

- Vehicle Year: 2006

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

- Rank: Offroad Rated

fishsticks wrote:Me likey! Will probably steal ideas from your build on this.

+1

Reading, looking at the pix, taking notes.

2008 TB, 1.75" Smaxx front, 1.25" wheel adapters, 255/75-17 Silent Armor, compass mirror, 7" indash DVD/GPS, power passenger seat, & Mikes steel skid plate.

-

Harry Moto - Member

- Posts: 92

- Joined: Sun Nov 14, 2010 12:13 am

- Location: AZ Mesa, Arizona

- Name: Harry

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

The TECORE 5 guys may know my compressor kicked the bucket after airing up my tires and some of Matt's tires. In reality it had probably done the equivalent of more cycles than that, because I had a air leak in my air system that was bleeding air.

Anyhow, I finally got around to tearing it down yesterday and found that the connecting rod had separated from the drive yolk. It's simply pressed into place.

I don't have any pictures of my fix, but I removed a bit of the yolk so that the motor output's D would press into the connecting rod D due to the force from a set screw. Again - should have taken pictures. But if anyone runs into a similar problem and wants pictorial help, I can always tear the compressor down again and take pics.

---------------

One takeaway from my experience with a OBA system, is that a smaller tank could be a benefit. Mine comes in a bit above 4 gallons. I'd maybe recommend one gallon, or a way to bypass the air tank. The benefit of the air tank basically runs out after the first two tires, because the tank gets down to the pressure of the tires. So now instead of airing up a 7 gallon tire, you're effectively airing up an 11 gallon tire. So whenever I revisit this system again, I think I will put in an option to bypass the tank once the tank's pressure decreases below a beneficial level.

Anyhow, I finally got around to tearing it down yesterday and found that the connecting rod had separated from the drive yolk. It's simply pressed into place.

I don't have any pictures of my fix, but I removed a bit of the yolk so that the motor output's D would press into the connecting rod D due to the force from a set screw. Again - should have taken pictures. But if anyone runs into a similar problem and wants pictorial help, I can always tear the compressor down again and take pics.

---------------

One takeaway from my experience with a OBA system, is that a smaller tank could be a benefit. Mine comes in a bit above 4 gallons. I'd maybe recommend one gallon, or a way to bypass the air tank. The benefit of the air tank basically runs out after the first two tires, because the tank gets down to the pressure of the tires. So now instead of airing up a 7 gallon tire, you're effectively airing up an 11 gallon tire. So whenever I revisit this system again, I think I will put in an option to bypass the tank once the tank's pressure decreases below a beneficial level.

-

Trail X - Founder

- Posts: 9925

- Joined: Mon Sep 07, 2009 10:22 pm

- Location: VA, Roanoke

- Name: James Downing

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Expedition Guide

JamesDowning wrote:The TECORE 5 guys may know my compressor kicked the bucket after airing up my tires and some of Matt's tires. In reality it had probably done the equivalent of more cycles than that, because I had a air leak in my air system that was bleeding air.

Anyhow, I finally got around to tearing it down yesterday and found that the connecting rod had separated from the drive yolk. It's simply pressed into place.

I don't have any pictures of my fix, but I removed a bit of the yolk so that the motor output's D would press into the connecting rod D due to the force from a set screw. Again - should have taken pictures. But if anyone runs into a similar problem and wants pictorial help, I can always tear the compressor down again and take pics.

---------------

One takeaway from my experience with a OBA system, is that a smaller tank could be a benefit. Mine comes in a bit above 4 gallons. I'd maybe recommend one gallon, or a way to bypass the air tank. The benefit of the air tank basically runs out after the first two tires, because the tank gets down to the pressure of the tires. So now instead of airing up a 7 gallon tire, you're effectively airing up an 11 gallon tire. So whenever I revisit this system again, I think I will put in an option to bypass the tank once the tank's pressure decreases below a beneficial level.

I vote for the bypass vs the smaller tank. Having a good size tank will give you enough air to set a bead on a tire.

That said, I understand what you mean. My 5 gal tank is good for one of my tires from 15 to 30ish.

I own too many vehicles now. Let's leave it at that.

The old Trailblazer - Build

The old Trailblazer - Build

-

fishsticks - Moderator

- Posts: 4358

- Joined: Thu Apr 01, 2010 11:30 pm

- Location: WA, Castle Rock

- Name: Donny

- Vehicle Year: Other

- Vehicle: Other Vehicle

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Extreme Offroader

Alright so I did a big party foul and PM'd JD some questions about this when I should've posted here originally. So I got the gasketed bulkhead for the hose going from the compressor through the sheetmetal to the tank and the one way valve to prevent back flow. Here's another question. Is the manifold what controls the compressor turning on automatically at certain levels or something else. Most of my wiring knowledge is radio based and cat5e/6 based haha

Last edited by Blazintrails03 on Mon Apr 01, 2013 4:22 pm, edited 1 time in total.

The unofficial hat guy of ORTB viewtopic.php?f=7&t=4325

BUILD THREAD: viewtopic.php?f=74&t=5377&p=106362#p106362

BUILD THREAD: viewtopic.php?f=74&t=5377&p=106362#p106362

- Blazintrails03

- Trail-Blazer

- Posts: 359

- Joined: Mon Apr 30, 2012 8:56 pm

- Location: VA, Manassas

- Name: Bobby

- Vehicle Year: 2003

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

- Rank: Trail Ready

The manifold is just a block with holes in it. The pressure trigger is what signals the relay, which provides power to the compressor.

The pressure trigger is the item on the manifold that has the wires coming out of it.

The pressure trigger is the item on the manifold that has the wires coming out of it.

-

Trail X - Founder

- Posts: 9925

- Joined: Mon Sep 07, 2009 10:22 pm

- Location: VA, Roanoke

- Name: James Downing

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Expedition Guide

Thinking about it while working today I might just hard mount it where you did James and run the hose through the same way but just run it to the winch hole for the spare. Later on if I want to throw a tank under there I will. Also will probably put an adapter on the hose that came with the mv50 to extend a 25 foot coiled hose I get that way it will reach all 4 tires no problem. The spare will of course be carrier or roof mounted so I won't have to worry about blocking that hole

The unofficial hat guy of ORTB viewtopic.php?f=7&t=4325

BUILD THREAD: viewtopic.php?f=74&t=5377&p=106362#p106362

BUILD THREAD: viewtopic.php?f=74&t=5377&p=106362#p106362

- Blazintrails03

- Trail-Blazer

- Posts: 359

- Joined: Mon Apr 30, 2012 8:56 pm

- Location: VA, Manassas

- Name: Bobby

- Vehicle Year: 2003

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

- Rank: Trail Ready

It's fine running it without a tank. Just keep in mind that you do not want to run it with a hose attached that has a shutoff valve. If you do, you will likely blow your hose. You will at least need a blowoff valve in line.

Reading back through, I realized I never updated this thread. I did get a new MV50, and its been working much better than the old one and runs much faster. I think they have a fairly finite life span - and are nearly irreparable since they have very limited service parts. I had attempted to fix my old one twice, and neither time it held together for very long.

Glad I read back through it though - it reinforced my need for a tank bypass valve.

Reading back through, I realized I never updated this thread. I did get a new MV50, and its been working much better than the old one and runs much faster. I think they have a fairly finite life span - and are nearly irreparable since they have very limited service parts. I had attempted to fix my old one twice, and neither time it held together for very long.

Glad I read back through it though - it reinforced my need for a tank bypass valve.

-

Trail X - Founder

- Posts: 9925

- Joined: Mon Sep 07, 2009 10:22 pm

- Location: VA, Roanoke

- Name: James Downing

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Expedition Guide

JamesDowning wrote:It's fine running it without a tank. Just keep in mind that you do not want to run it with a hose attached that has a shutoff valve. If you do, you will likely blow your hose. You will at least need a blowoff valve in line.

I'm saying just hard mounted and lined to the bumper so I can just reach in, turn it on and use it, and then turn it off. I wouldn't have it on at all times. Would I still need the valve?

The unofficial hat guy of ORTB viewtopic.php?f=7&t=4325

BUILD THREAD: viewtopic.php?f=74&t=5377&p=106362#p106362

BUILD THREAD: viewtopic.php?f=74&t=5377&p=106362#p106362

- Blazintrails03

- Trail-Blazer

- Posts: 359

- Joined: Mon Apr 30, 2012 8:56 pm

- Location: VA, Manassas

- Name: Bobby

- Vehicle Year: 2003

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

- Rank: Trail Ready

All depends on what hose end you have to fill tires. If it has a valve, you would need the blowoff.

-

Trail X - Founder

- Posts: 9925

- Joined: Mon Sep 07, 2009 10:22 pm

- Location: VA, Roanoke

- Name: James Downing

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Expedition Guide

33 posts

• Page 2 of 2 • 1, 2